If your disposable glove choices are based on price alone, take time to consider glove surface characteristics at a microscopic level, and why this affects food safety.

Significant differences exist between glove types and even within the same glove type, all based on raw material formulations and standards of manufacturing. We’ve taken the time to review these differences at a microscopic level, so you can better understand glove micro failures and surface characteristics.

Fractography

Fractography is the study of the fracture surfaces of materials |

Fractography is the study of the fracture surfaces of materials and is routinely used to determine the cause of product failures or failure analysis.

Fractography of disposable gloves is the study and assessment of their surface failure characteristics, and gives insights into damage occurring during manufacturing, accounting for the differences in glove durability. It is a vital tool in understanding the differences in failure rate between and within glove types, and allows comparisons for purposes of evaluating glove performance.

In order to define a glove’s material structure, the first step is to consider the fracture surfaces with the naked eye, and then use higher and higher magnification in order to resolve the structures leading to failure.

Fractography of Vinyl Gloves

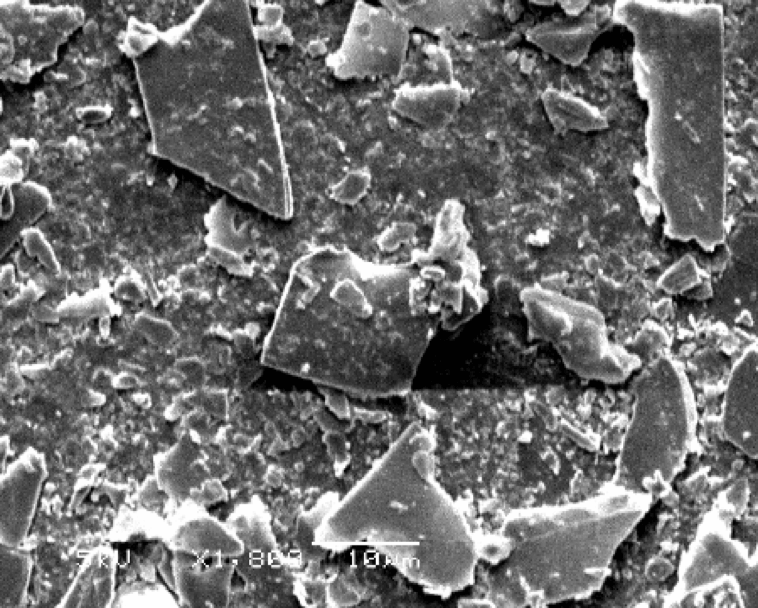

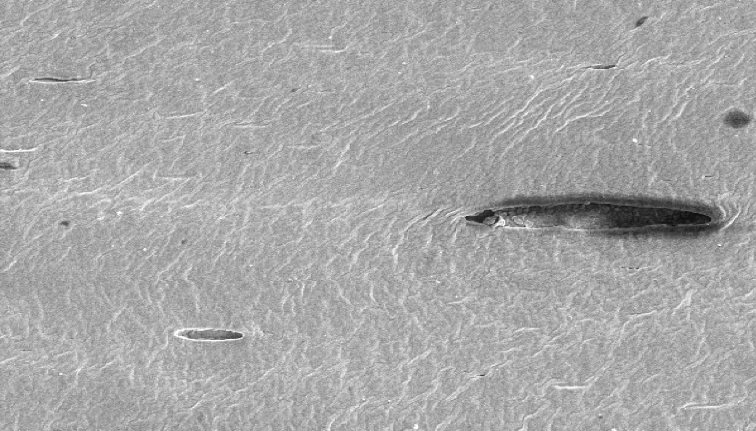

Up to 50% of disposable vinyl (PVC) gloves are made up of plasticizers, which make the PVC flexible and soft enough to wear. When viewed under an electron microscope, pinholes and failures in plasticized vinyl compounds can be seen. These micrometer-sized failures are not visible to the naked eye and become a perfect opportunity for the spread of pathogens unbeknown to the glove wearer.

|

|

| Fractures along well-defined crystallographic planes in brittle PVC vinyl gloves - similar to that found in metals that are loaded repeatedly (Scanning Electron Microscope 1,800 X). These crystals are identified as plasticizers measuring 0.5 to 1.5 µm in size. | Vinyl glove punctures when stretched (Scanning Electron Microscope 400 X). |

There are more than 250 different foodborne diseases associated with food or drink, and studies show that up to 18,000 Staphylococci can pass through a single glove hole during a 20-minute period, even though the hands had been scrubbed for 10 minutes prior to gloving (Guzewich & Ross 1999). There is ample opportunity for vinyl gloves with high failure rates to share responsibility for pathogen transmission (Todd et al. 2010b).

Fractography of Nitrile Gloves

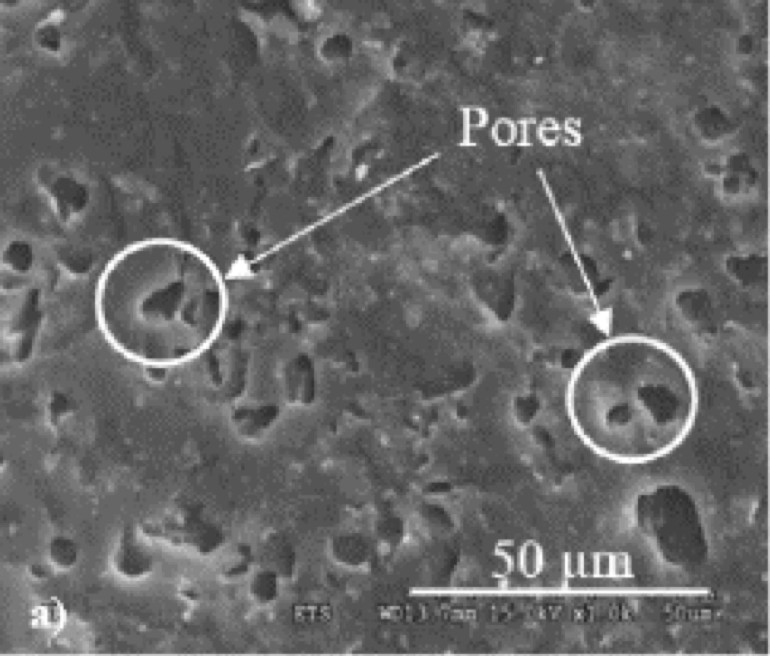

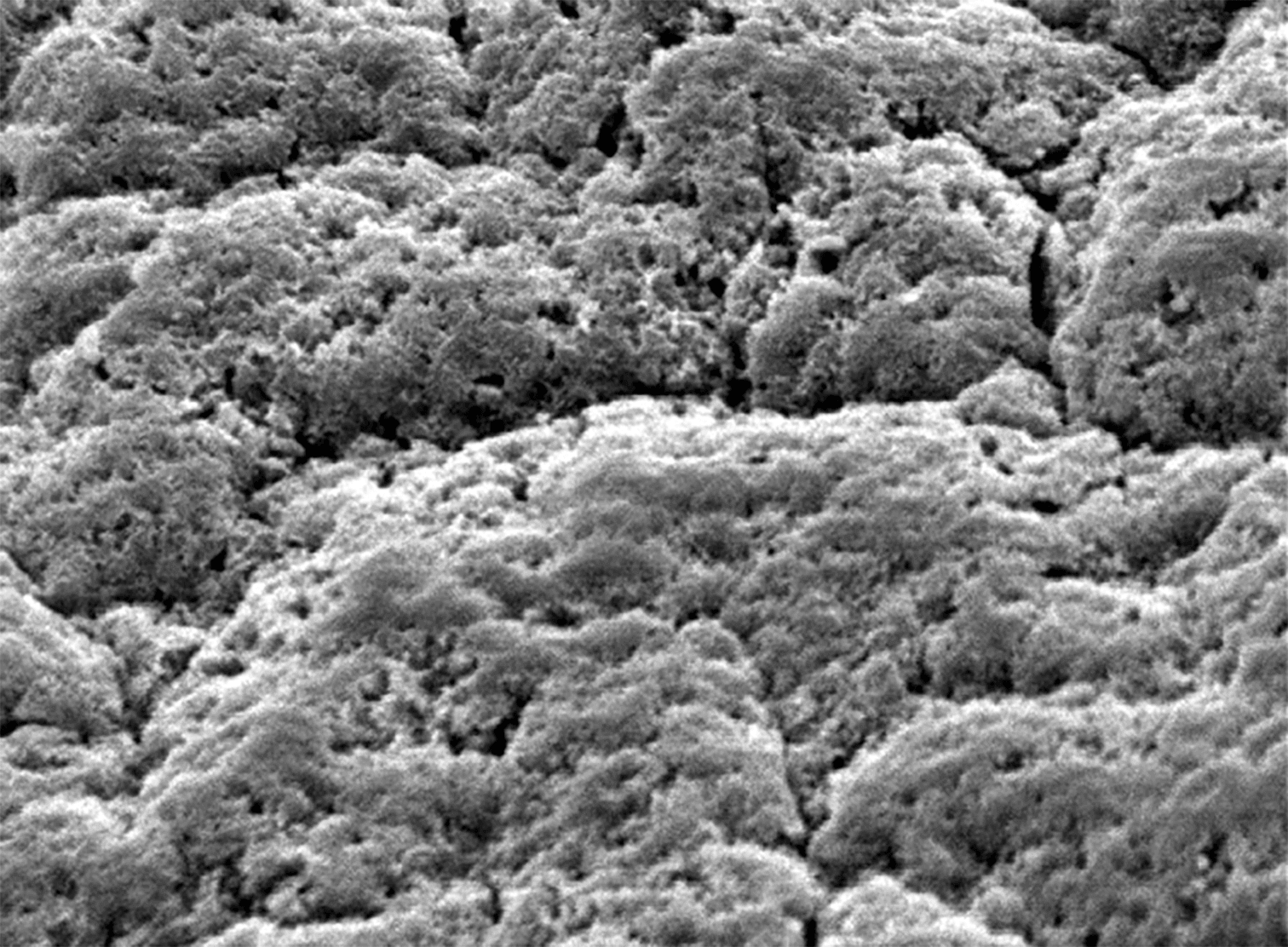

Manufacturing standards, including the raw materials from which nitrile gloves are made, vary significantly between each type of nitrile glove. When viewed by the naked eye, there can be little or no difference in glove quality seen. However, when viewed under an electron microscope, variations between nitrile gloves surfaces are evident.

|

|

| Micrometer-sized pores evident in thin poor quality nitrile gloves (Vinches et al. 2014). (Scanning Electron Microscope 900 X) | Newer engineered, smoother nitrile glove (Scanning Electron Microscope 1,800 X) |

Differences in raw material formulations affect quality (failure rate) and glove physical chemistry, and subsequently contribute to the cross-contamination potential of disposable gloves for food handling.

When choosing a food safe disposable glove, consider what you can’t see with your naked eye. Microscopic glove failures and surface characteristics can and do lead to pathogen transmission to food. Why take this risk?

Written by: Lynda Ronaldson, VP Marketing

References

Guzewich J. and Ross MP. 1999. Evaluation of Risks Related to Microbiological Contamination of Ready-to-eat Food by Food Preparation Workers and the Effectiveness of Interventions to Minimize Those Risks. USFDA/CFSAN White Paper. September 1999.

Todd E, Michaels BS, Greig JD, Holah J, Smith D and Bartleson CA. 2010b. Outbreaks Where Food Workers Have Been Implicated in the Spread of Foodborne Disease: Part 8: Gloves as Barriers to Prevent Contamination of Food by Workers. Journal of Food Protection 73(9):1762-73.

Vinches L, Halle S, Peyrot C, Wilkinson KJ. 2014. Which Gloves are Efficient to Protect Against Titanium Dioxide Nanoparticles In Work Conditions. Int. J. Theoret. & Applied Nanotech. 1:1929-1248. DOI:10.11159/ijtan.2014.004.