Tapping into his 22 years of experience supplying PPE to the meat industry, there aren’t many parts of a meat processing plant Kyle Geary hasn’t been on. “Throughout my years and time on plant, you get to see every department, from slaughter to fabrication to deli meats. All of it.”

Tapping into his 22 years of experience supplying PPE to the meat industry, there aren’t many parts of a meat processing plant Kyle Geary hasn’t been on. “Throughout my years and time on plant, you get to see every department, from slaughter to fabrication to deli meats. All of it.”

Sitting down to talk about protective clothing in the jerky industry, Kyle shared what he’s encountered over the years.

We’ve been supplying the meat industry in New Zealand for 15 years. As Eagle is expanding across the globe, we’ve been able to share that experience with the US industry as well. We’ve taken customer feedback, spent time in processing plants talking to production people, and invested in refining our products to be customized to meet all industry demands.

Product Dispensing System

For instance, our disposable smocks are supplied on a hard header block. This allows the plant to hang the smocks on the wall, easily dispense one garment at a time, eliminate floor contamination and allow workers to get right to work. It’s all about efficiency. You don’t want workers messing around with extra garments or having to clean up the floor. You want them to grab a garment and get to work. Our smocks are great. They’re cost-effective. And since they protect clothing from getting splashed and soiled, they reduce laundering costs that are honestly pretty difficult to quantify with all of the clothing changes, maintenance, and cleaning involved. The smocks also reduce water use and what’s more, when they’re separated, they’re recyclable.

For instance, our disposable smocks are supplied on a hard header block. This allows the plant to hang the smocks on the wall, easily dispense one garment at a time, eliminate floor contamination and allow workers to get right to work. It’s all about efficiency. You don’t want workers messing around with extra garments or having to clean up the floor. You want them to grab a garment and get to work. Our smocks are great. They’re cost-effective. And since they protect clothing from getting splashed and soiled, they reduce laundering costs that are honestly pretty difficult to quantify with all of the clothing changes, maintenance, and cleaning involved. The smocks also reduce water use and what’s more, when they’re separated, they’re recyclable.

Material Quality: Virgin LDPE Plastic

Another example is the material our disposable clothing line is made of. Jerky production doesn’t deal with a lot of sharps (i.e. blades and knives) so snagging isn’t a big issue, LDPE (low-density polyethylene) plastic is great for this. It’s designed to stretch before it breaks so it won’t split into small pieces and become a foreign contaminant. Eagle clothing is made of virgin plastic material. There are no fillers used. The virgin plastic guarantees the quality of plastic you get and creates a whiter, cleaner, and more hygienic look. It’s not that we recommend against recycled plastic clothing, but it makes it a bit harder to guarantee the material quality.

Another example is the material our disposable clothing line is made of. Jerky production doesn’t deal with a lot of sharps (i.e. blades and knives) so snagging isn’t a big issue, LDPE (low-density polyethylene) plastic is great for this. It’s designed to stretch before it breaks so it won’t split into small pieces and become a foreign contaminant. Eagle clothing is made of virgin plastic material. There are no fillers used. The virgin plastic guarantees the quality of plastic you get and creates a whiter, cleaner, and more hygienic look. It’s not that we recommend against recycled plastic clothing, but it makes it a bit harder to guarantee the material quality.

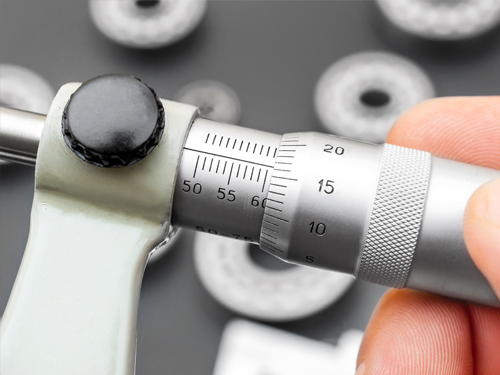

Garment Thickness

From our history and experience, 28-30μm (1.1 - 1.2mil) thick garments perform well in jerky processing. We wouldn’t recommend anything less than that. It is a bit of a challenge when talking disposable clothing with a plant, to get them to understand the thickness and durability of our clothing line. Often the first thing they think is, ‘Is that a big heavy raincoat’ and it’s really not. They are thinner and with high durability, but it’s a challenge to verbally describe. I find the best way is to get a sample in their hands and just have them try it.

From our history and experience, 28-30μm (1.1 - 1.2mil) thick garments perform well in jerky processing. We wouldn’t recommend anything less than that. It is a bit of a challenge when talking disposable clothing with a plant, to get them to understand the thickness and durability of our clothing line. Often the first thing they think is, ‘Is that a big heavy raincoat’ and it’s really not. They are thinner and with high durability, but it’s a challenge to verbally describe. I find the best way is to get a sample in their hands and just have them try it.

Priority: Plant Hygiene

Changing systems in any jerky or meat plant is always a pretty good challenge. Once they use an item it becomes the norm. Our main focus is providing a hygienic product, one that protects clothing and the worker. Our garments stem from our experience in NZ where hygiene is paramount. Government export rules and their actual presence on meat plants themselves dictate the most hygienic processes, and LDPE clothing is part of that.

Changing systems in any jerky or meat plant is always a pretty good challenge. Once they use an item it becomes the norm. Our main focus is providing a hygienic product, one that protects clothing and the worker. Our garments stem from our experience in NZ where hygiene is paramount. Government export rules and their actual presence on meat plants themselves dictate the most hygienic processes, and LDPE clothing is part of that.

Are you interested in learning more about Eagle’s disposable clothing line? Contact our team of experts who are ready to answer any questions you may have.

Are you currently using reusable protective clothing? Learn the advantages and disadvantages of each type, both disposable and reusable.